BEMCOT™ Wipers for Electronic Screen Printing

BEMCOT™ Wipers for Electronic Screen Printing

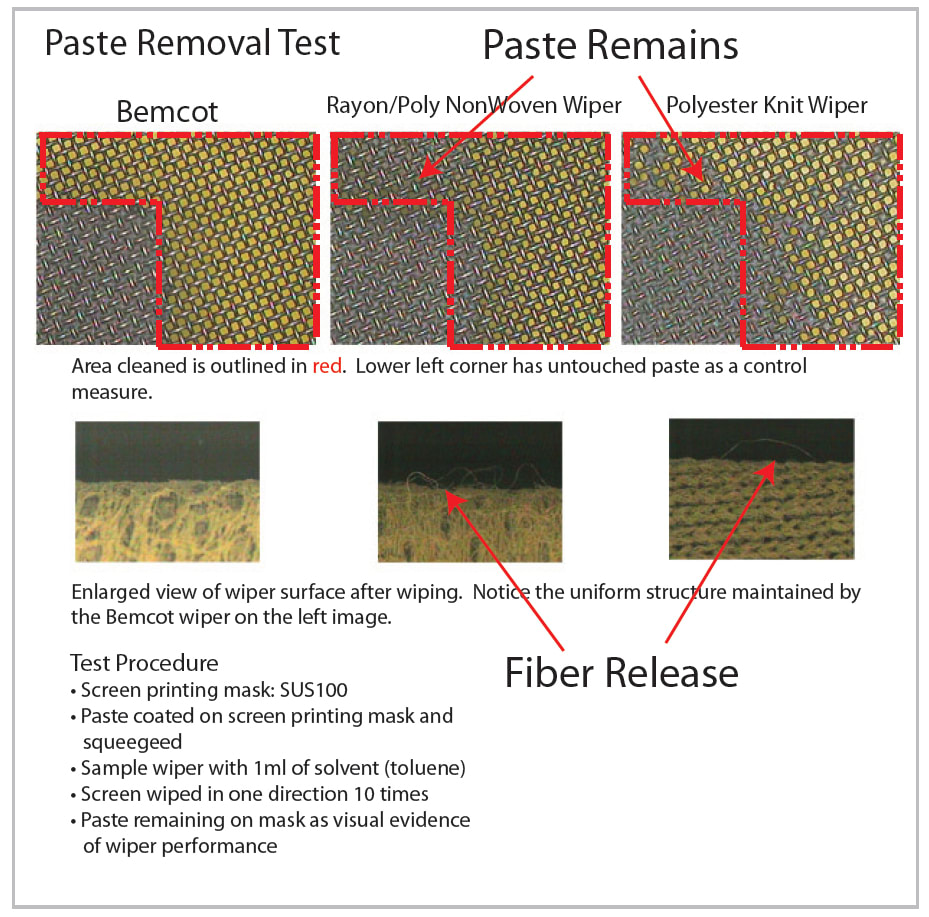

During the electronic screen printing process, an excess amount of paste remains that polyester or other wipers cannot remove effectively.

The solution: Bemcot Wipers

Why Bemcot Lint-Free Wipers?

With over twenty years as the cleanroom wiper of choice in Japan, Bemcot are the only wipers made from Bemliese™, the 100% pure cellulosic nonwoven fabric derived from cotton linter. The Bemliese production process forms a pure nonwoven sheet by self-bonding continuous filaments with no binder or other additives. Bemcot wipers provide a unique combination of key advantages using renewable natural cotton linter:

- Low particle generation

- Anti-static

- High purity

- Heat resistance

- High absorbency

- Biodegradability

- High chemical resistance

- Ecoefficiency

BEMCOT is used by Toyota, Honda and other Top Automotive Manufacturers in Japan.

Key Benefits for Electronics Screen Printing

1. High Absorption: For removing paste (aluminum, copper, silver, etc.)

2. Lint Free: Ultra-low fiber release for maintaining clean surface areas

3. Mesh Pattern:Â Bemcot wipers have unique mesh pattern for excellent paste removal

4. Exceptional Price Performance: 1/2 to 1/3 price of polyester knit wipers

5. Green: Biodegradable and ecoefficient – 100% natural cotton linter

Typical Usage for Automotive Surface Preparation

Paste Removal: Removing excess paste after squeegee process. The typical application for electronic screen printing includes PCB, LCD, Touch Panel, Capacitor, etc. utilizing electrode printing, solder printing, sealing resin printing, and fluorescent substance printing

Learn More About BEMCOT M3 Cleanroom ESD Wipers or Fill Out The Form Below.